|

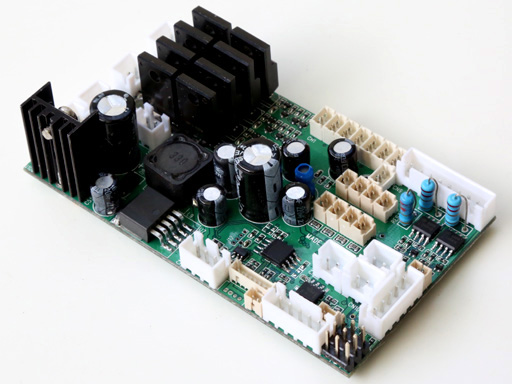

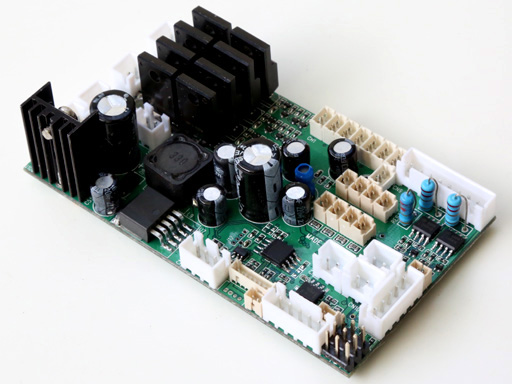

MFK-02 Series RC Excavator

Controller |

MFK-02,

a highly integrated RC Excavator controller,

for

upgrading BRUDER excavator

into proportional radio control with Light and Sound Effect

MFK02 series controller uses

8 channels/10-CH S.BUS RC system to control R/C Excavator MFK02 series controller uses

8 channels/10-CH S.BUS RC system to control R/C Excavator

60A motor driver

60A motor driver

High quality sound with digital sound

mixer

High quality sound with digital sound

mixer

10W

sound output power 10W

sound output power

Safety shutoff prevents

unwanted movement while signal lost Safety shutoff prevents

unwanted movement while signal lost

Auto R/C signal detection, suitable for 27M, 72M and 2.4G RC system

Auto R/C signal detection, suitable for 27M, 72M and 2.4G RC system

|

|

MFK-02S |

MFK-02 |

|

Remote Control System

|

10-CH S.BUS 2.4G RC system |

Traditional 4-CH AM, FM or 2.4G RC system |

|

Engine Sound rendering

|

Multi

Simple Set,

Fuzzy Logic Engine Sound Simulation |

Multi

Simple Set,

Fuzzy Logic Engine Sound Simulation |

|

Motor driver Current

|

60A ( 540 Motor) |

60A ( 540 Motor) |

|

Kit contained |

MFK-02S board *1,

S.BUS cable*1 |

MFK-02 board *1,

channel cable*8 |

|

Reference Price |

TBD |

TBD |

|

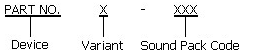

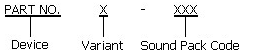

Product

Identification System |

| Device |

MFK-02 |

MFK-02

excavator

controller |

| |

|

|

|

Variant |

Blank |

Standard,

Equal to P Variant in TK60 series

|

| |

S |

Support S.BUS

interface |

| |

P |

Sound

Programmable |

| |

|

|

|

Sound Pack |

CAT |

CAT |

| |

|

|

| |

|

|

| |

|

|

|

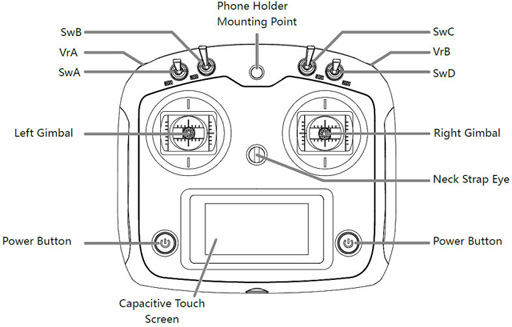

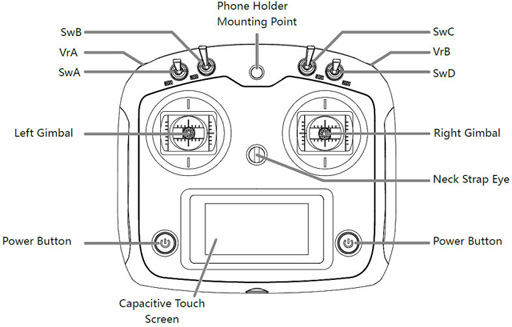

MFK-02S

10-CH S.BUS control scheme( Based on FS-i6S transmitter +

FS-iA10B Receiver ) |

Transmitter: FS-i6S, self-centering VrA

and VrB type Radio

RX:FS-iA10B

|

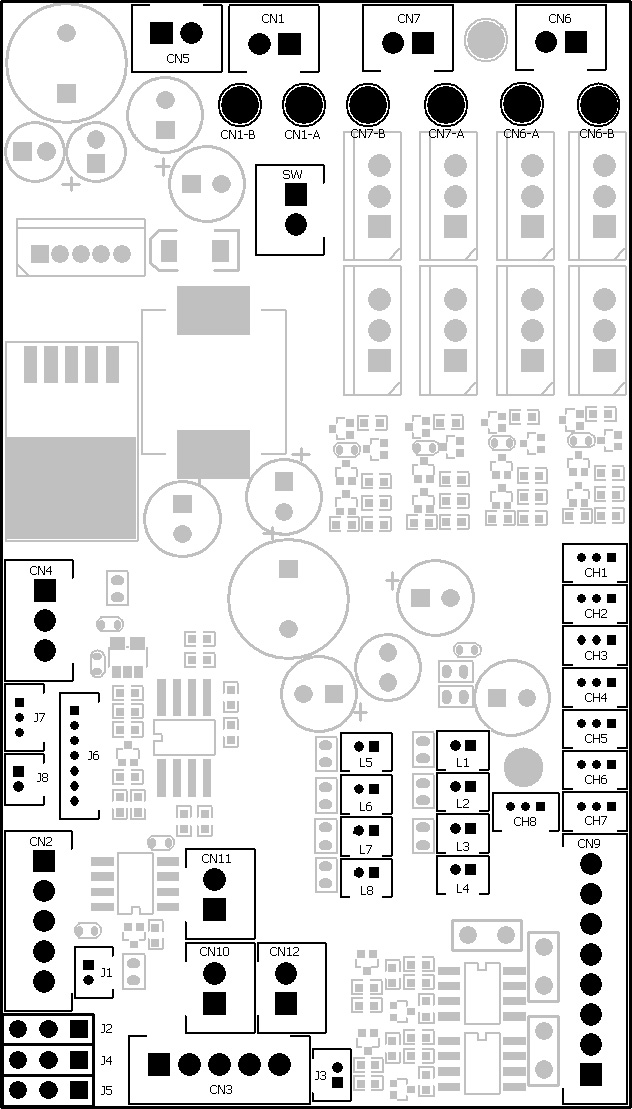

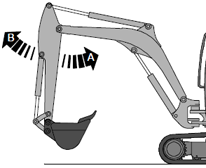

Layout |

Command |

S.BUS

Channel

assignment |

|

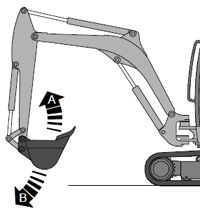

CH2

CH1 |

Close/open bucket

|

CH1 (Stick)

To do: pass to servo port |

|

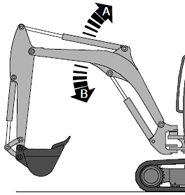

CH2

CH1 |

Dipper In/Out

|

CH2 (Stick) |

|

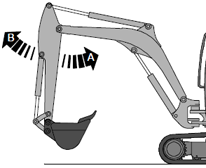

CH4

CH3 |

Raise

/ Lower boom

|

CH3

(Stick)

To do: pass to servo port |

|

CH4

CH3 |

Slew

cab left / right

|

CH4

(Stick)

To do: pass to servo port |

|

SwA/KeyA |

Horn |

Assign SwA/KeyA to CH5 |

|

SwB: Center -> Up |

Engine start/stop |

Assign SwB to CH7 |

|

SwB Center -> Down |

Rotating Light On/Off |

Assign SwB to CH7 |

|

SwC: Center -> Up |

Controlled Switch(L4) on/ff,

can used to control

|

Assign SwC to CH8 |

|

SwC: Center -> Down |

Head Light

On / Off |

Assign SwC to CH8 |

|

SwD |

UP:

Smoke Unit

On

DW:

Smoke Unit Off

|

Assign Key2 to CH6 |

|

VrA |

Left Track Control Lever |

Assign VrA to CH9 |

|

VrB |

Right

Track Control Lever

|

Assign VrB to CH10 |

|

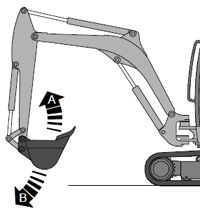

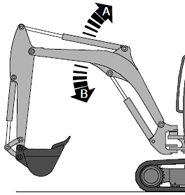

MFK-02

4-CH Control Mode and operation |

|

|

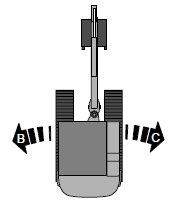

Left Track Move forward and

backward |

|

|

|

Right Track Move forward and

backward |

|

|

|

Horn |

|

|

|

Engine

On/Off |

|

|

|

Head

Light On/Off |

|

|

|

Rotating

Light On/Off |

|

|

CH5 |

Boom Down/Up |

|

|

CH6 |

Dipper IN/OUT |

|

|

CH7 |

Bucket CURL/Dump |

|

|

CH8 |

Swing Left and Right |

|

|

Parameter

|

|

Unit

|

|

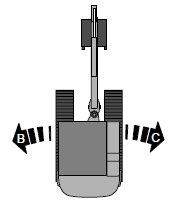

Maximum current of track ESC |

60 |

A |

|

Maximum current of turret and

cannon elevation ESC |

7 |

A |

|

Maximum current of Smoker Driver |

7 |

A |

|

Maximum supply

voltage |

7.4

|

V |

|

Minimum supply

voltage |

7.2 |

V |

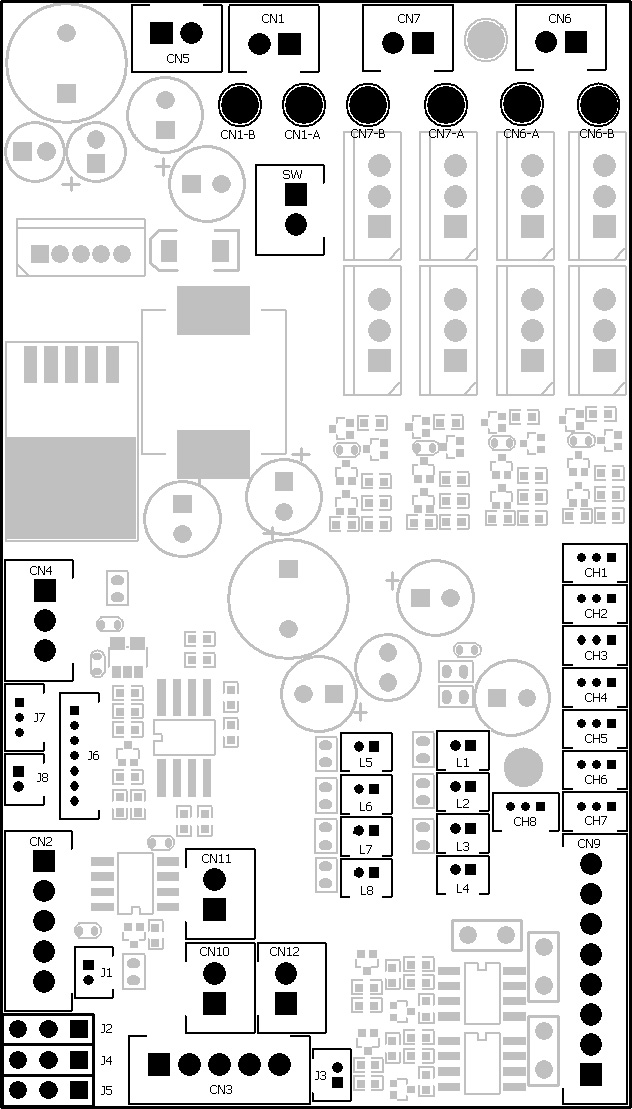

MFK series connector and pin assignments

MFK-02S Pin assignment

|

Connector

|

Description

|

Note |

|

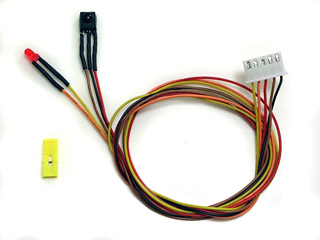

SW |

Switch Cable Port |

Connect to switch cable

|

|

CN1

|

Battery Power

|

1. Battery +

2.

Battery -

|

|

CN2 |

IR Configuration

Port |

1.

IR

Configuration

receiver +

2.

IR

Configuration

receiver SIG

3.

IR

Configuration

receiver -

4. IR

Configuration Indicator

LED -

5. IR

Configuration Indicator

LED +

|

|

CN3 |

NA |

|

|

CN4 |

Sound

Volume |

1.

Volume Signal

Output (

Wiper pin of VR

)

2. Battery -( 1 outside pin of

VR )

3.

Volume

Signal

Input (

1 outside pin of VR ) |

|

CN5 |

Speaker |

|

|

CN6

|

Left Track ESC

|

|

|

CN7

|

Right Track ESC |

|

|

CH1

|

|

|

|

CH2

|

|

|

|

CH3 |

|

|

|

CH4

|

|

|

|

CH5 |

|

|

|

CH6 |

|

|

|

CH7 |

|

|

|

CH8 |

|

|

|

CN9 |

Light

Effect Functions |

1.

2.

Head Light LED-

3.

Head Light LED+

4.

5.

6.

7.

Cab slew motor

+

8.

Cab slew motor

- |

|

CN10 |

NOT USED |

|

|

CN11 |

NOT USED |

|

|

J1 |

|

|

|

J2 |

Boom Servo

Port |

1. Signal( White Wire)

2.

+5V ( Red Wire)

3. Battery - (Black Wire) |

|

J3 |

|

|

|

J4 |

Dipper

Servo Port |

1. Signal( White Wire)

2.

+5V ( Red Wire)

3. Battery - (Black Wire) |

|

J5 |

Bucket

Servo Port |

1. Signal( White Wire)

2.

+5V ( Red Wire)

3. Battery - (Black Wire) |

|

J6 |

NA |

|

|

J7 |

S.BUS/TK-LINK

Port |

To

connect S.Bus Receiver

1. N/A

2.

Battery -

3.

S.BUS RX

4.

TK-LINK TX |

|

J8 |

NA |

|

|

L1 |

Rotating

Light LED1

|

1. LED +

2. LED - |

|

L2 |

Rotating

Light LED2

|

1. LED +

2. LED - |

|

L3 |

Rotating

Light LED3

|

1. LED +

2. LED - |

|

L4 |

Controlled SW/Tail Light |

When

connect to a motor:

1. Motor +

2. Motor -

When connect to a

LED:

1. 200ohm in-serial resistor --> LED +

2. LED -

Maximum Current : 7A |

|

L5 |

Head Light LED 1 |

1. LED +

2. LED - |

|

L6 |

Head Light LED 2 |

1. LED +

2. LED - |

|

L7 |

NA |

|

|

L8 |

NA |

|

MFK-02 Pin assignment

|

Connector

|

Description

|

Note |

|

SW |

Switch Cable Port |

Connect to switch cable

|

|

CN1

|

Battery Power

|

1. Battery +

2.

Battery -

|

|

CN2 |

IR Configuration

Port |

1.

IR

Configuration

receiver +

2.

IR

Configuration

receiver SIG

3.

IR

Configuration

receiver -

4. IR

Configuration Indicator

LED -

5. IR

Configuration Indicator

LED +

|

|

CN3 |

NA |

|

|

CN4 |

Sound

Volume |

1.

Volume Signal

Output (

Wiper pin of VR

)

2. Battery -( 1 outside pin of

VR )

3.

Volume

Signal

Input (

1 outside pin of VR ) |

|

CN5 |

Speaker |

|

|

CN6

|

Engine Vibration

Motor

|

|

|

CN7

|

Driving Motor |

|

|

CH1

|

Multi function control

signal 1

|

Futaba: CH1

JR:AILE

|

|

CH2

|

Left Track

|

Futaba:

CH2( Mode 2) or CH3 ( Mode 1 )

JR:ELEV

|

|

CH3 |

Right Track |

Futaba:

CH3( Mode 2) or CH2 (

Mode 1 )

JR:THRO

|

|

CH4

|

Multi function control

signal 2

|

Futaba: CH4

JR:RUOD

|

|

CH5 |

Boom |

Futaba: CH5

|

|

CH6 |

Dipper |

Futaba: CH6

|

|

CH7 |

Bucket |

Futaba: CH7 |

|

CH8 |

Swing |

Futaba: CH8 |

|

CN9 |

Light

Effect Functions |

1.

2.

3.

4.

5.

6.

7.

Swing Motor

+

8.

Swing

Motor - |

|

CN10 |

NOT USED |

|

|

CN11 |

NOT USED |

|

|

J1 |

IR Battle Emitter

Port/ Reverse Light |

To work

with IR battle emitter(IR010)

1. IR LED +

2. IR LED - |

|

J2 |

Boom Servo

Port |

1. Signal( White Wire)

2.

+5V ( Red Wire)

3. Battery - (Black Wire) |

|

J3 |

|

|

|

J4 |

Dipper

Servo Port |

1. Signal( White Wire)

2.

+5V ( Red Wire)

3. Battery - (Black Wire) |

|

J5 |

Bucket

Servo Port |

1. Signal( White Wire)

2.

+5V ( Red Wire)

3. Battery - (Black Wire) |

|

J6 |

NA |

|

|

J7 |

NA |

|

|

J8 |

NA |

|

|

L1 |

Rotating

Light LED1

|

1. LED +

2. LED - |

|

L2 |

Rotating

Light LED2

|

1. LED +

2. LED - |

|

L3 |

Rotating

Light LED3

|

1. LED +

2. LED - |

|

L4 |

NA

|

|

|

L5 |

Head Light LED 1 |

1. LED +

2. LED - |

|

L6 |

Head Light LED 2 |

1. LED +

2. LED - |

|

L7 |

NA |

|

|

L8 |

NA |

|

Under

construction!

|

Board Personalization( Patent Pending) |

Parameters

of MFK series board can be set by

Configuration IR REMOTE

and programming line.

Steps

to set parameters:

Steps

to set parameters:

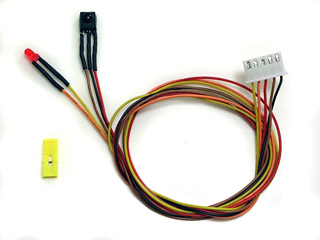

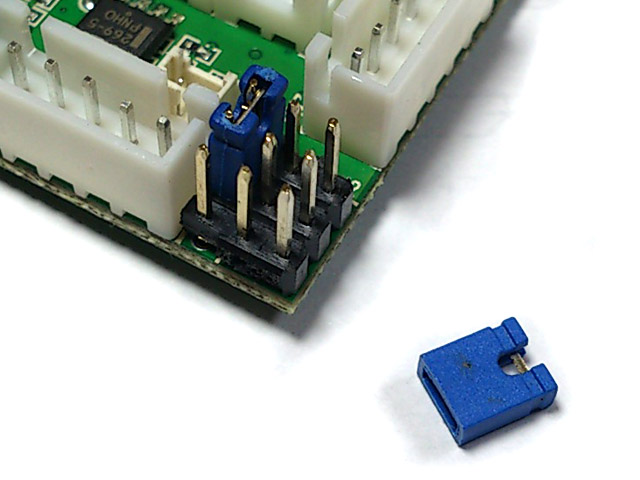

STEP 1:

Turn power off, plug programming line to CN2(

IR Configuration

Port )

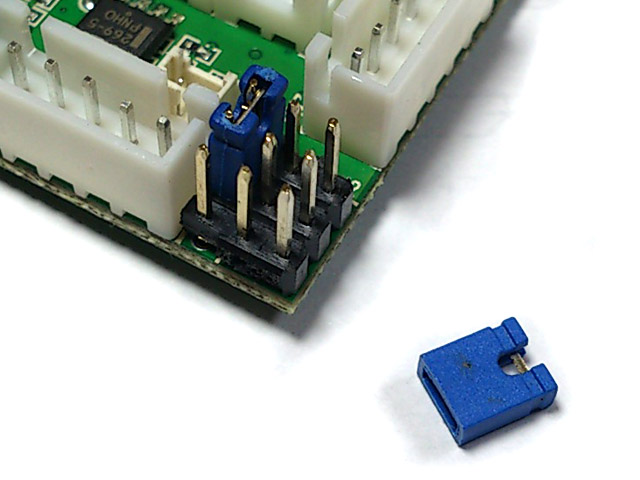

STEP 2: Install a jumper to J2

as shown below, turn power on,

STEP 3: Point

Configuration IR remote to

programming line receiver,

refer to function table listed below and press the

button

of function that you want to set,

STEP 4: Indicator of

programming line flashes according to

new

setting value.

STEP 5: turn power off, remove

jumper on J2, then power on and you are set.

Function tables:

Function tables:

Save

current setting to

PRESET 1: Press number

key "1" on TV remote to save,

|

Available Settings |

Indicator

flashes times |

Description |

|

Save to

PRESET 1 |

1 |

Indicator flashes when setting

is saved

|

Save

current setting to PRESET 2: Press number

key "2" on TV remote to save,

|

Available Settings |

Indicator

flashes times |

Description |

|

Save to

PRESET

2 |

2 |

Indicator flashes when setting

is saved

|

*Once

you've adjusted everything, you can

push "1" or

"2" to save

current setting to PRESET 1

or 2. If you don't do this saving the board remembers

the last settings.

Use saved settings:

Press "ENT" or "SOUND MODE" Key on TV remote to select.

|

Available Settings |

Indicator

flashes times |

Description |

|

Use

PRESET 1

setting |

1 |

|

|

Use

PRESET 2 setting |

2 |

|

|

Use Factory Default Setting

( Read-Only ) |

3 |

To

restore factory

default value in case of setting data is messed up. |

*To

switch between the presets you press either "sound

mode" or "enter" button, once the preset is selected,

switch tank off and remove setup jumper. Switch back on and away you

go.

On-the-move alarm sound On/Off:

Press "Timer

Off(0x3C)"

or "

"on TV remote to select "on TV remote to select

|

Available Settings |

Indicator

flashes times |

Description |

|

On |

1* |

|

|

Off |

2 |

|

Q:

A:

MADE

IN TAIWAN

|